We were approached by our customer who required the complete supply of precision parts, foam inserts, labels and Peli case – Rout 1 was uniquely placed to supply and manufacture all aspects of the project. The specially designed microscope carrier was to be used to inspect a safety-critical area for damage and micro-cracking, this required a combination of materials to be used including stainless steel and nylon.

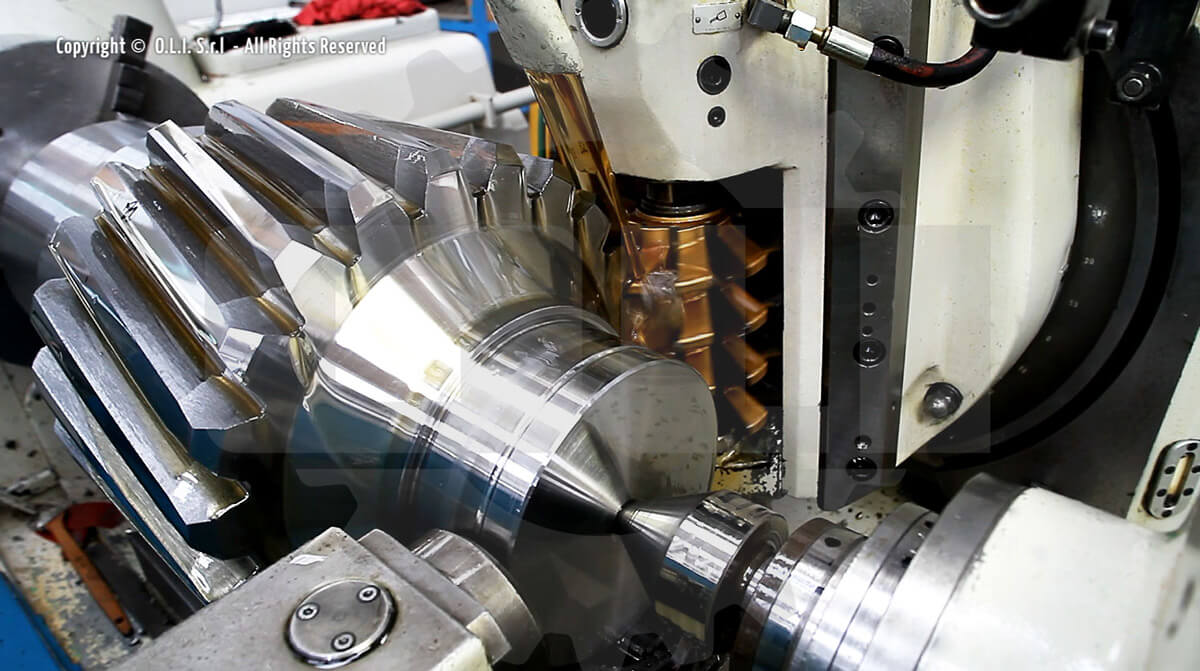

The stainless steel microscope interface was a complex part with tight tolerance bore an M40 x 1mm pitch male thread and fixing bracket. Due to the shape of the part thread milling was the only way to produce the M40 thread. The Peli case required an engraved label to identify it and the foams inserts were designed to securely hold the precision parts and the delicate microscope.

Rout 1 manufactured, in house, every part required to the specified high tolerances, supplied an inspection report and the Peli case, foam inserts & labels complete.